Per una migliore visualizzazione, consigliamo di ruotare lo schermo dello smartphone.

I. Product sanitisation

CAUSE: Product unplugged or not working for more than 2 weeks, new installation or suspected mains water pollution

SOLUTION: Any suitable sanitising solution can be used, following manufacturer's instructions. Otherwise, use a 130-volume hydrogen peroxide (hydrogen peroxide) solution at a concentration of 5% per litre of water.

Sanitisation procedure:

- Prepare 5 litres of sanitising solution

- Close the water valve at the product inlet and disconnect it from the water mains

- Using a pump, connect the product water inlet to the container with the sanitising solution

- Provide a suitable container at the product dispensing points

- Start the pump by introducing the sanitising solution into the product and then, at the same time, dispense from all lines so that the sanitising solution flows to all points of the water circuit, up to the dispensing spout

- Before the sanitising solution runs out, stop the pump and stop dispensing

- Disconnect the product from the container that contained the sanitising solution

- Allow the sanitising solution to act for at least 20 minutes

- Reconnect the product to the water mains

- Flush the product adequately by dispensing from all lines a total of at least 60 litres of water

ATTENTION: Sanitisation is recommended:

- when first installed

- whenever components of the hydraulic circuit are replaced

- if pollution occurs or is suspected

- product is installed in new premises

I. The LED on the keyboard is steady

CAUSE: Activation of the automatic safety system

SOLUTION: To reset the carbonation system, simply unplug the product from the socket, wait a couple of minutes and reconnect it.

Under normal operating conditions, the pump remains active approximately 30 seconds after dispensing sparkling water. In the event of low inlet water pressure or excessive sparkling water dispense, a safety system automatically deactivates the sparkling water production system in order to protect the internal components. This shutdown causes only carbon dioxide instead of sparkling water to escape.

ATTENTION: a low inlet pressure can damage the pump located in the water sparkling circuit and the continuous tripping of the electronic protection.

I. The LED on the keyboard is steady

CAUSE: Activation of the automatic safety system

SOLUTION: To reset the carbonation system, simply unplug the product from the socket, wait a couple of minutes and reconnect it.

Under normal operating conditions, the pump remains active approximately 30 seconds after dispensing sparkling water. In the event of low inlet water pressure or excessive sparkling water dispense, a safety system automatically deactivates the sparkling water production system in order to protect the internal components. This shutdown causes only carbon dioxide instead of sparkling water to escape.

ATTENTION: a low inlet pressure can damage the pump located in the water sparkling circuit and the continuous tripping of the electronic protection.

I. The LED on the keyboard flashes

CAUSE: 6 months have passed or more than 3000 litres have been dispensed since the product was last serviced

SOLUTION: Carry out a general maintenance of the product, including the replacement of filters (if present). Then proceed to reset the counters.

Reset procedure:

- Switch off the product (or disconnect it from the mains)

- Press the extreme keys on the keypad simultaneously (usually chilled and room temperature water)

- Still with the buttons pressed, switch the product back on (or reconnect it to the mains)

- Release the buttons after at least 3 seconds

ATTENTION: The LED will make 10 quick flashes to confirm that the reset procedure was successful.

I. The chilled and/or sparkling water is at room temperature

PRIOR VERIFICATION: Leave the product running for at least 20 minutes without dispensing any beverages and then check the temperature of the air coming out of the ventilation slots.

SOLUTION: If air is:

- COLD: The cooling unit of the product is not working - Contact an Authorised Technical Center

- WARM:

- If the ambient temperature is below 23/27 ºC, the chilling unit is operating - Wait a couple of hours before dispensing again

- If the ambient temperature is above 23/27 ºC, the refrigerating unit is not working - Contact a Authorised Technical Center

- HOT: The cooling unit is working properly - Wait a couple of hours before dispensing again

- VERY HOT: The cooling unit is working properly:

- The product cannot dissipate heat properly - Ensure that the ventilation grids are free of obstacles and there are no heat sources (e.g. coffee machines, ovens, etc.) nearby

- The product is overused - Reduce chilled water dispensing and wait at least a few hours before dispensing again

When switching the product on for the first time, wait at least a couple of hours before dispensing chilled still and/or sparkling water.

ATTENTION: The product must be installed in such a way that the ventilation grids are at least 25 cm away from any matching bulkhead.

I. Sparkling water is not carbonated enough

CAUSE: Presence of air in the sparkling circuit and/or the reducer is set too low.

SOLUTION: Remove the air in the sparkling circuit and/or increase the value set on the reducer by 1 bar.

To remove the air in the sparkling circuit:

- Close the water valve at the product inlet

- Dispense sparkling water until only carbon dioxide comes out

- Dispense only carbon dioxide for 2-3 seconds. Repeat this operation a couple of times

- Re-open the water valve at the product inlet

- Wait for the pump to fill the carbonator (should be evident from the noise)

- Dispense some sparkling water and test the level

This procedure can be repeated as many times as necessary to increase mixing efficiency.

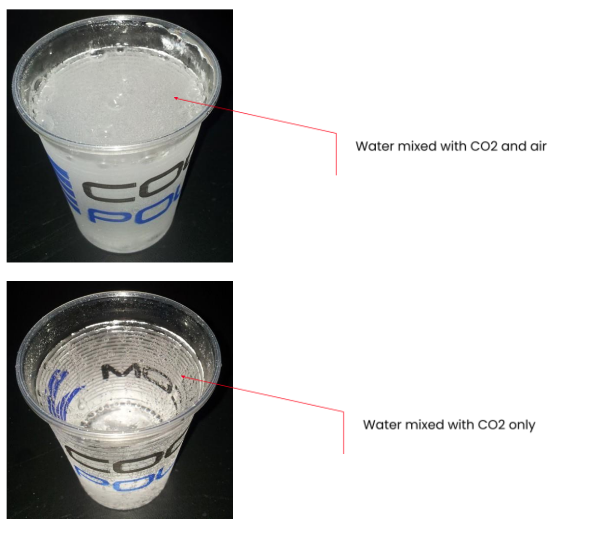

ATTENTION: The presence of air in the water circuit drastically reduces the effectiveness of mixing water and CO2. This condition is evidenced by the whitish/milky colour of the sparkling water.

I. No sparkling water and only carbon dioxide comes out

CAUSE: Activation of the automatic safety system

SOLUTION: To reset the sparkling system, simply unplug the product from the socket, wait a couple of minutes and reconnect it.

Under normal operating conditions, the pump remains active approximately 30 seconds after dispensing sparkling water. In the event of low inlet water pressure or excessive sparkling water dispense, a safety system automatically deactivates the sparkling water production system in order to protect the internal components. This shutdown causes only carbon dioxide instead of sparkling water to escape.

ATTENTION: a low inlet pressure can damage the pump located in the water sparkling circuit and the continuous tripping of the electronic protection.

I. The sparkling water is not carbonated or the delivery is too slow

CAUSE: The carbon dioxide cylinder is empty or the reducer is set too low.

SOLUTION: Replace the carbon dioxide cylinder or increase the value set on the reducer by 1 bar.

The level of carbonation depends solely on the mixing of CO2 with water.

ATTENTION: the value set on the pressure reducer must NOT exceed 0.45 MPa (4.5 bar). Above this value, the pressure safety valve on the pressure reducer itself could open, causing the carbon dioxide cylinder to suddenly empty.

I. No sparkling water and only carbon dioxide comes out

CAUSE: Activation of the automatic safety system

SOLUTION: To reset the sparkling system, simply unplug the product from the socket, wait a couple of minutes and reconnect it.

Under normal operating conditions, the pump remains active approximately 30 seconds after dispensing sparkling water. In the event of low inlet water pressure or excessive sparkling water dispense, a safety system automatically deactivates the sparkling water production system in order to protect the internal components. This shutdown causes only carbon dioxide instead of sparkling water to escape.

ATTENTION: a low inlet pressure can damage the pump located in the water sparkling circuit and the continuous tripping of the electronic protection.

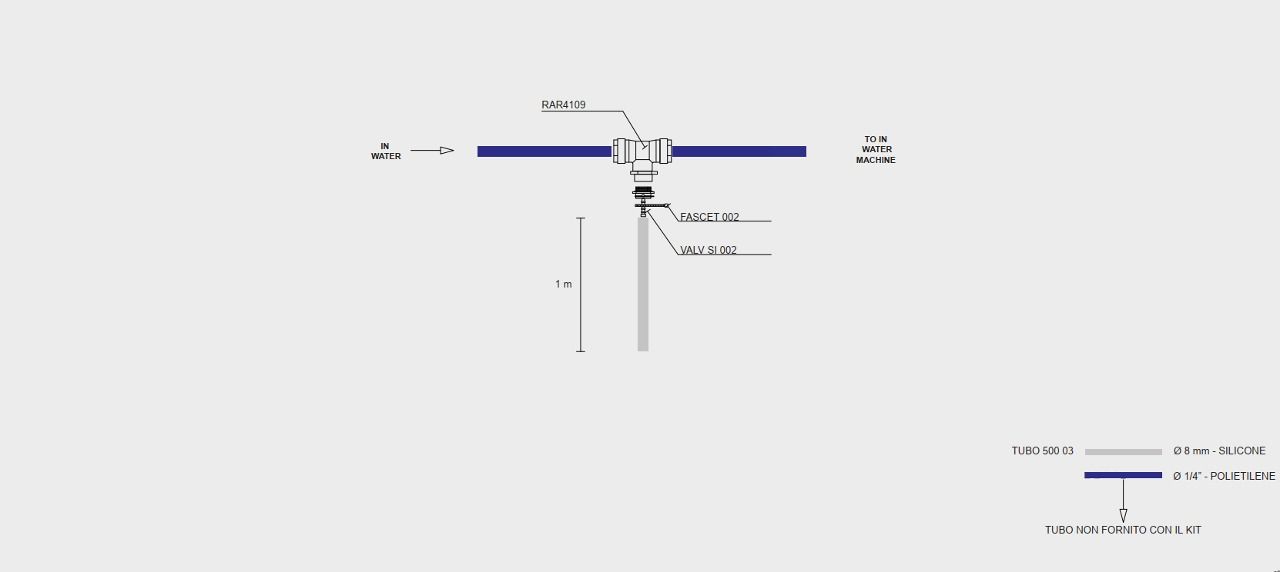

I. Where is the overpressure kit installed?

The system should be installed immediately before the Zerica product, as in the picture: